Christine Rankin

Communications Officer, Faculty of Engineering, McMaster University

MMRI engages learners in training programs and discovers cutting-edge innovations for industry partners.

The next wave of diverse talent in a growing sector of the advanced manufacturing economy is arising at the McMaster Manufacturing Research Institute (MMRI).

As manufacturers contend with the challenges involved in new production technology, automation, and a quest to leverage data to make better decisions, the MMRI is finding solutions in its resources: world-class facilities, industrial-scale equipment, and the crux of innovation — its people.

The industrial training program at the MMRI is securing the bright minds and expertise needed to innovate and adopt new technologies to add value and enhance functionality.

“Challenging problems drive great research and learning opportunities. Seeing solutions through to implementation ensures economic impact and job creation in Canada,” says MMRI director Stephen Veldhuis. “As we see significant opportunities in industry arise — those involving electric vehicles, aerospace, and energy, particularly nuclear, as well as the medical and food sectors — training the new wave of skilled workers to assist companies has become crucial to delivering cutting-edge results.”

In addition to working with industry, the MMRI is also partnering with groups that already have strong connections in the community.

The YWCA Hamilton Uplift Program, supported by the Federal Economic Development Agency (FedDev) for Southern Ontario, provides women and non-binary people the opportunity to reskill or upskill in, among other fields, advanced manufacturing.

Micro-credentials within the nine-month programming occur at the MMRI, where participants expand their skills — in materials, manufacturing processes, automation, Lean, and Industry 4.0 — and readiness for leadership roles that are under-represented by women.

“The YWCA Hamilton Uplift Program helps participants achieve advanced positions, job security, and higher salaries in advanced manufacturing (and other high-tech industries in Ontario) where there’s a need for greater gender equality,” says Kelley Evans, Uplift Program Coordinator — Advanced Manufacturing.

Lina Tabares, a software engineer with aerospace experience, was one of the participants. “All classes have more than met my expectations,” Tabares says. “It’s a wonderfully practical training course, both personally and professionally. I feel more empowered. Online classes have helped me express myself better, and the new skills I’ve gained have opened many doors for me.”

Wardah Al-Juboori, a water hydraulics/hydrological engineering specialist, says they’re taking away improved knowledge, particularly in the field of Industry 4.0, materials testing, and management. “My understanding of the field of advanced manufacturing has expanded and I’ve become more confident and convinced that women can be leaders and hold a leadership role in this important field,” Al-Juboori says. “The program has changed my resume to a more targeted and powerful one.”

The MMRI has created 311 new jobs and trained 1,353 people as part of the various training and research experiences generated through close collaborations with industry and community partners.

“Engaging learners in this problem-solving process enriches their learning experience and provides them with the hands-on skills they need to succeed in industry. With strong support from McMaster University, and our industry, federal, and provincial government partners, we’re growing the next generation of talent and connecting them with real career-building experiences,” says Veldhuis.

MMRI is finding solutions in its resources: world-class facilities, industrial scale equipment, and the crux of innovation, its people.

In order to accommodate growing relationships with a wide range of automotive OEMs (original equipment manufacturers), aerospace companies, medical device makers, and companies in the energy sector, the MMRI is expanding, adding capability and improving access to its resources.

A new 21,000-square-foot advanced manufacturing research facility will open this fall at the McMaster Innovation Park. It will be conveniently situated by Highway 403 and strategically placed among McMaster’s key innovators to ensure that Canada’s innovations are made here and supplied globally

The facility will help the MMRI accelerate its research program and provide more opportunities for technical experts to stay ahead of the curve.

The institute is involved in the Ontario Advanced Manufacturing Consortium and the FedDev Ontario-supported Southern Ontario Network for Advanced Manufacturing Innovation (SONAMI) and iHub programs, which offer expertise to industry partners and finding practical solutions to difficult, real-world problems.

Partner companies like Quickmill and Racer are working with the MMRI to train new users of advanced manufacturing equipment through the training program. Meanwhile, the institute has assisted those companies in developing unique capability for their manufacturing machines, which target many opportunities including electric motor manufacturing and new developments in the nuclear industry. Those machines are now for sale.

The MMRI Open House will return this fall at a new location: a 21,000-square-foot advanced manufacturing research facility at McMaster Innovation Park. Details to be revealed this summer on the MMRI website: mmri.mcmaster.ca

Ruyan (Daisy) Dai

Product developer for a food manufacturer and participant of the YWCA Hamilton Uplift Program

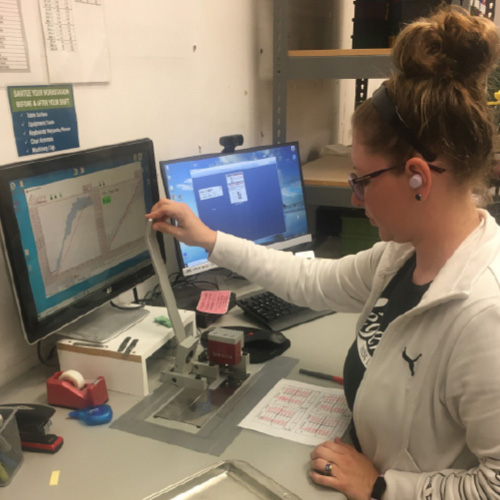

Candice Butler

CNC operator at Legere Reeds and participant of the YWCA Hamilton Uplift Program

Lina Tabares

Software engineer and participant of the YWCA Hamilton Uplift Program

Tammy Chen

Project manager at Edge Eyewear and participant of the YWCA Hamilton Uplift Program